Views: 158 Author: Site Editor Publish Time: 2025-07-22 Origin: Site

Motorized rollers have become an essential component in modern conveyor systems, offering efficiency, automation, and precise movement control. However, a common question often arises during system design and equipment selection: do all motorized rollers carry the same weight? The answer is not as simple as it may seem. Variations in roller design, motor power, material composition, and intended applications mean that different motorized rollers have vastly different load-bearing capacities. This article delves into the nuances of motorized rollers and the key factors that influence their weight-bearing abilities.

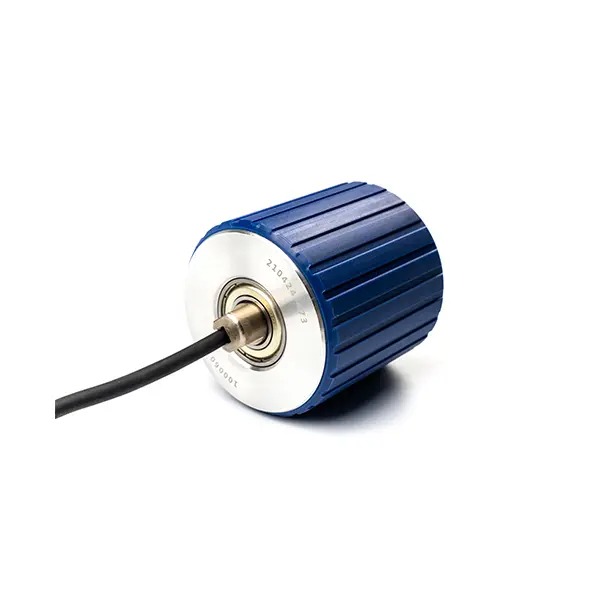

Motorized rollers, also known as drum motors or powered rollers, are cylindrical devices integrated with a motor inside the roller itself. Unlike traditional conveyor systems that use external motors, motorized rollers offer a more compact and efficient way to power conveyor belts or roller conveyors.

These rollers are widely used in industries such as e-commerce, manufacturing, food processing, and warehousing. By eliminating the need for chains, belts, and gearboxes outside the roller body, they reduce maintenance costs and enhance safety. However, while they serve a common purpose, not all motorized rollers are built the same.

The design specifications for a motorized roller—such as diameter, motor wattage, internal gearing, and casing material—can significantly affect its ability to carry weight. A roller designed for light-duty parcel handling will not perform well under the heavy loads required in industrial pallet transport.

The physical dimensions of a motorized roller play a crucial role in determining its load-bearing capability. A roller with a larger diameter and thicker wall is structurally more capable of handling heavier loads. Small-diameter rollers (e.g., 50mm) are typically used for light-duty applications like small parcel transport, whereas larger diameters (e.g., 89mm or more) are engineered for pallet handling or heavy goods.

Increased wall thickness also enhances resistance to deflection under load. When selecting rollers, engineers must consider both the diameter and thickness based on the expected load distribution per meter of conveyor length.

Motor power, usually measured in watts, directly affects the torque that a roller can produce. Higher torque translates to a greater capacity to move heavier items. Furthermore, the gear ratio inside the roller motor assembly determines the speed-torque tradeoff. A roller geared for high speed may not support heavy loads, while one geared for torque will perform better in high-load environments, albeit at a slower pace.

For example, a 60W motorized roller might be suitable for a 50kg load, while a 200W roller could carry loads exceeding 200kg, depending on the application context and layout.

The composition of the roller's outer shell—such as steel, stainless steel, or reinforced plastic—affects its strength and durability. Steel rollers are generally used for heavy-duty applications, while plastic or aluminum variants are reserved for lightweight products.

Surface treatments like rubber lagging or poly-coated rollers also affect traction, which is essential in maintaining consistent load movement without slippage, especially when dealing with sloped or fast-moving conveyors.

| Roller Diameter (mm) | Motor Power (W) | Typical Load Capacity (kg) | Ideal Use Case |

|---|---|---|---|

| 50 | 20 – 60 | Up to 50 | Small parcels, electronics |

| 60 | 60 – 100 | Up to 100 | Lightweight cartons, trays |

| 80 | 100 – 180 | 100 – 200 | General goods, totes |

| 89 | 180 – 250+ | 200+ | Pallets, bulk materials |

This table illustrates the range of motorized rollers available on the market and how their specifications determine their optimal usage and load capacity.

Yes, they absolutely do. Even if two motorized rollers appear to have identical specifications—such as motor wattage and diameter—the actual materials used, internal construction, cooling efficiency, and quality control standards can vary greatly between manufacturers. This leads to differing actual performance outcomes.

It’s essential for engineers and procurement specialists to carefully read technical datasheets and, if possible, request performance testing results for specific load cases. Weight capacity should never be assumed based purely on diameter or wattage alone.

In parcel sorting and distribution, lightweight packages dominate. Here, speed and efficiency are prioritized over load capacity. Motorized rollers used in such settings typically have lower wattage and smaller diameters, as the average package rarely exceeds 25kg.

For food handling, stainless steel rollers with medium load capacities are common. While individual items may be light, the total load on the conveyor can increase rapidly due to bulk containers or accumulation zones.

For applications like automotive manufacturing or palletized cargo movement, robust motorized rollers with reinforced construction and high-power motors are required. These rollers often come with built-in brakes, advanced feedback systems, and programmable logic for precise motion control.

Understanding the weight requirements for each industry is key to selecting the correct roller type and ensuring operational efficiency and equipment longevity.

Yes, but it may not be the most cost-effective or energy-efficient option. Over-specifying rollers increases upfront costs and may cause issues such as excessive wear or energy waste.

Calculate the total weight of items per meter of conveyor, divide by the number of rollers per meter, and then factor in safety margins and peak loads. Consult engineering standards and roller datasheets for accurate results.

Overloading can cause excessive heat buildup, motor burnout, structural deformation, or complete system failure. Most high-quality rollers include overload protection, but consistent overloading will significantly reduce service life.

Some regions and industries require compliance with specific standards (e.g., ISO, CE). Look for third-party test certifications or regulatory marks to ensure product reliability.

The assumption that all motorized rollers carry the same weight is not only incorrect—it can also lead to serious design flaws, equipment failure, and safety hazards. Motorized rollers are engineered with distinct specifications tailored to different industrial needs, and their load capacities vary widely.

When choosing a motorized roller, it is essential to evaluate the full range of performance indicators—not just the motor wattage or roller diameter. Material, construction, intended use, surface treatments, and operating environment all contribute to a roller's actual capacity and suitability.

Whether you're designing a high-speed distribution line or a heavy-duty manufacturing conveyor, selecting the appropriate motorized roller is not just about function—it’s about optimizing performance, safety, and long-term return on investment.